PET/PE Metallic offers excellent protection against moisture, UV radiation and oxygen. The combination of PET and PE creates a stable and impermeable packaging that reliably protects your products.

Further advantages of our PET/PE Metallic

Excellent barrier properties

Attractive look

The shiny, metallic surface of PET/PE Metallic gives your products a particularly appealing and high-quality look. This visual appeal can improve the perception of your brand and draw customers' attention to your products.

Stability and tear resistance

Thanks to the robust combination of PET and PE, the metallic film offers high puncture resistance. This stability ensures that the packaging remains intact even under demanding conditions and that your products are safe and protected.

Technical characteristics

Top quality in every layer: The details of our PET/PE Film Metallic

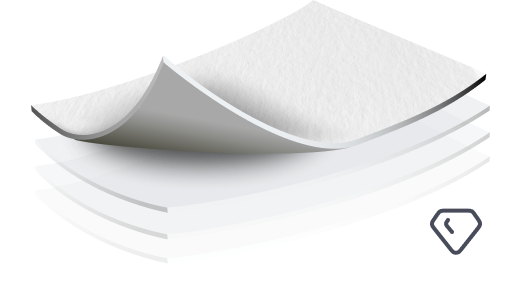

Our PET/PE Metallic is highly complex in its composition and offers optimum protection for your product. The following breakdown shows the different layers and their function:

OPP-Matt Layer

OPP-Matt Layer

The outermost layer protects the design from color abrasion and prevents the color from coming into direct contact with food. Depending on the finish, this layer can offer a matt, glossy or soft-touch feel, allowing the packaging to be customized.

PET Metallic Layer

PET Metallic Layer

The middle layer gives the packaging its characteristic metallic look. It also serves as a high barrier against oxygen and water vapor, which guarantees the shelf life and freshness of the products. Furthermore, this layer gives the packaging its rigidity and ensures a stable and resistant structure.

PE Layer

PE Layer

The innermost layer is responsible for sealing the pouch. It ensures that the pouch remains stable and cannot be opened unintentionally. At the same time, it contributes to the exceptional robustness of PET/PE Films, making them more resistant than PP Films.

PET/PE Metallic impresses with its sophisticated layer structure, which perfectly combines functionality and aesthetics. The top OPPmatt layer protects the design, ensures color brilliance and offers an individual feel depending on the finish. PET/PE Metallic layer gives your film its unique metallic look and acts as a high barrier against oxygen and water vapor, ensuring the durability of the products. The PE layer ensures a secure seal and gives the packaging exceptional stability. This combination makes PET/PE Film a versatile and robust solution for high-quality packaging.

Further advantages of our PET/PE Metallic

Our PET/PE Metallic outstanding aroma and grease barriers, keeping your products fresh and clean. With customizable features like Velcro zippers and versatile finishes—from matte to soft-touch—it combines practicality with a high-end look, perfect for a variety of uses.

Individual customizability

With our individual extras such as the Velcro zipper, you can make the packaging not only functional but also practical - ideal for multiple applications and easy handling.

High aroma density

PET/PE Metallic provides an excellent aroma barrier, which ensures that odors and aromas remain inside the packaging. This is particularly important for food and other products whose aroma and freshness need to be preserved.

Grease resistance

Thanks to its high resistance to grease, PET/PE Metallic is ideal for packaging fatty foods. It prevents grease from penetrating and keeps the packaging clean and stable.

Flexibility in finishing

Whether matt, glossy or soft-touch - the versatile finishing options open up numerous design options and offer a high-quality look.

Differences and similarities

PET/PE vs. PP

Recyclability

Stability

External stress

Individual Extras

Barrier properties

Excellent against oxygen and moisture

Print properties

Ideal for high-quality print results

Similarities

- Both types of film offer excellent barrier properties against oxygen and moisture, keeping the contents fresh and protected.

- They are ideal for high-quality printing results and enable individual design options.

- Both materials can be equipped with individual extras to extend their functionality.

Differences

Recyclability:

While PP Films are recyclable as a mono-material, PET/PE is not recyclable due to its material composition.

Stability:

PET/PE Films are more robust and resistant than PP Films, which makes them particularly suitable for heavy or sensitive products.

Custom Extras:

The PET/PE Film is available with a Hook-to-Hook Zipper, which offers additional functionality and user-friendliness.

External Stress:

PET/PE Films withstand external influences such as mechanical stress or extreme storage conditions even better than PP Films and therefore offer maximum safety for the contents.

The choice between PET/PE and PP depends on your specific requirements. PET/PE is ideal for maximum stability and a classy look. If sustainability and recyclability are a priority, PP Films are the better choice.

Versatile in use

Discover the applications of our PET/PE Metallic

Our PET/PE Film Metallic offers a wide range of applications, from food packaging to cosmetics. Its unique properties make it particularly suitable for various industries where both protection and attractive presentation are crucial.

Food packaging

Food packaging

The metallic surface of our PET/PE Metallic offers excellent flavor protection and preserves the freshness of the products. The film is also grease-resistant, which makes it particularly suitable for packaging fatty foods.

Example: snacks, nuts, dried fruit, sweets, powdered products

Cosmetic packaging

Cosmetic packaging

Cosmetic products benefit from the robust and attractive packaging of PET/PE Metallic. The film protects the sensitive ingredients from external influences and presents the products in an attractive, shiny sleeve.

Example: creams, lotions, masks, bath additives

Pet food packaging

Pet food packaging

The PET/PE Film Metallic provides the necessary protection and stability required for pet food packaging. It keeps the products fresh and protects them from external influences.

Example: dry food, treats

Food supplements

Food supplements

The PET/PE Film Metallic protects sensitive food supplements from moisture and UV radiation in order to preserve the quality and effectiveness of the products.

Example: vitamins, minerals, protein powder, capsules

Coffee and tea packaging

Coffee and tea packaging

Coffee and tea need packaging that preserves their flavor and freshness. The PET/PE Film Metallic offers optimum protection against light and moisture.

Example: coffee beans, ground coffee, tea leaves, tea bags

Book a Pouch Expert

Do you need personal advice, help or guidance from one of our experts?

Everything at a glance: Technical data for download

Get detailed information on the technical specifications of our PET/PE metallic film. Perfect for anyone who needs precise data for their planning and production. Download the full technical data now and find out all about the properties and benefits of our high-quality material.

FAQ

Your questions - Our answers

What advantages does PET/PE Film Metallic offer?

Our PET/PE Film Metallic offers numerous advantages, including:

- Excellent barrier properties: protection against moisture, UV radiation and oxygen.

- Attractive appearance: Shiny, metallic surface for a high-quality presentation.

- High stability: Robust and tear-resistant.

- Grease resistance: Ideal for packaging fatty foods.

Which products is PET/PE Film Metallic particularly suitable for?

PET/PE Film Metallic is ideal for:

- Food packaging: Snacks, powdered products, sweets.

- Cosmetics packaging: Creams, lotions, masks.

- Pet food packaging: Dry food, treats.

- Food supplements: vitamins, minerals, protein powder.

- Coffee and tea packaging: Coffee beans, ground coffee, tea leaves, tea bags.

What sizes and shapes are available?

Our PET/PE Film Metallic is available in different shapes and sizes to meet the individual needs of your product. From stand-up pouches to customized packaging solutions, we offer tailor-made options.

Is the PET/PE Film Metallic recyclable?

No, our PET/PE Film Metallic is not recyclable. However, it offers a durable and robust packaging solution that ensures the protection and presentation of your products.

Can the PET/PE Film Metallic be printed on?

Yes, the shiny metallic surface of the PET/PE Film Metallic ensures brilliant and clear printing results. It is ideal for creative and eye-catching designs.

How can I obtain further information and samples?

You can download further information and technical data directly from our website. We also offer sample packs so that you can test the properties of our PET/PE Film Metallic for yourself.

Don't miss any more news! Sign up for our Pouch newsletter and receive regular updates on new products, exclusive offers and exciting packaging-related topics.